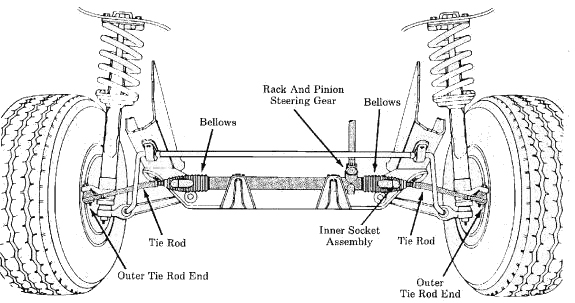

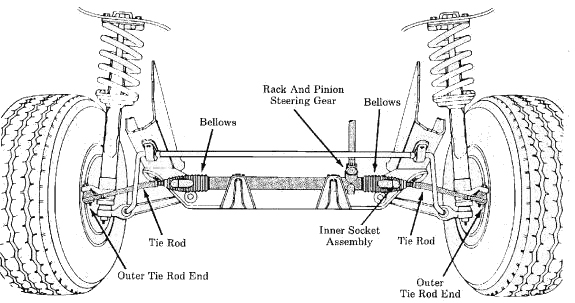

Why replace

rack-and-pinion steering rather than rebuild it

Overhauling a power rack is not a

job for the novice. Special tools are required to remove and

install internal seals. The tools are expensive and may not

be cost justified for a shop that only does an occasional

rack. For a do-it-yourselfer, the tools could end up costing

as much as a new or remanufactured rack.

It is tricky to get seals properly positioned. If a seal

slips or is damaged during installation, the rack will leak.

For that reason alone, many professional mechanics won't

waste their time trying to rebuild questionable racks.

Operating pressures within a power rack generally do not

exceed 100 psi when the wheels are in the straight-ahead

position. In an easy turn, the pressure can increase to as

much as 300 psi and it goes up to 700 psi in a tight turn.

The highest pressures are usually encountered when parking.

If the wheels are up against a curb or if the steering wheel

is turned hard against the stop, internal pressures can

climb to 700 to 1,400 psi. This is why anybody who overhauls

a rack better make sure the seals don't leak.

Time is another important factor to the professional

installers. Anything that makes their job easier and faster

is money in their pocket. If given a choice, most avoid

doing repairs the old fashioned way because overhauling

certain components in the shop slows them down and takes too

much time. That's why many components (like starters,

alternators, front-wheel drive driveshaft assemblies, even

brake calipers) are often replaced with new or

remanufactured units rather than overhauled in the shop. The

same is true for racks.

Time is money... and at $40 per hour it doesn't take long

for a mechanic's time to add up. By the time a mechanic

spends $25 to $30 for a seal kit and several hours

overhauling a rack (assuming it can be overhauled), he can

end up spending as much of his customer's money as if he had

bought a replacement rack in the first place.

Another reason why installers and do-it-yourselfers do not

rebuild their own racks is because some racks are not

rebuildable - at least not with a seal kit alone. If the

teeth in the center of the rack are worn or damaged, a

replacement rack bar can run $100 to $150.

If the housing is worn, distorted, cracked or otherwise

unusable, a new housing can cost upwards of $125. If the

control valve is bad, it will cost $150 to $250 to replace -

if you can find the parts. Individual component parts for

racks are not readily available in the aftermarket because

everyone knows it is cheaper and smarter to go with a new or

remanufactured rack if the original rack needs to be

overhauled.

Rebuilders can often salvage worn aluminum spool valve

housings by boring out the housings and installing a

stainless steel sleeve. The sleeve not only restores

tolerances, but also prevents the wear problem from

reoccurring. In that respect, a remanufactured rack may

actually be better than the original. Most rebuilders also

pressure test their racks after reassembly to make certain

they function correctly and do not leak.

One mistake installers should avoid when replacing a rack is

not flushing out the power steering pump and lines to remove

all traces of old fluid. Flushing is a must because it

removes contaminants that could ruin the replacement rack.

The system also needs to be purged of air by cycling the

steering slowly back and forth until there are no more air

bubbles in the fluid.

Related items that may also need replacing include rack

mounts and steering input shaft coupling. If the coupling

donut is deteriorating with age, it needs to be replaced.

Metal swivel couplings also need to be checked for rust and

binding. Do not forget to include new power steering fluid

(follow manufacturer recommendations as to the proper type

of fluid).

OneStop Auto Shop

Call Today for

all of your Auto Repairs

and Maintenance

in Hollywood, Ca.!

(323) 227-9999

|