Oxygen Sensor

How does the oxygen sensor work

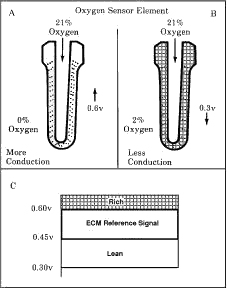

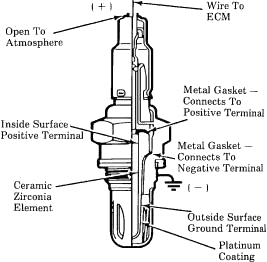

This is the only sensor that makes its own voltage. The voltage signal is proportional to the amount of unburned oxygen in the exhaust. When hot (at least 600 degrees |F), the zirconium dioxide element in the sensor’s tip produces a voltage signal that varies according to the difference in oxygen content between exhaust and outside air.

The higher the concentration of unburned oxygen in the exhaust, the lower the differential across the sensor tip and the lower the sensor’s voltage output. The sensor’s output ranges from 0.1 volts (lean) to 0.9 volts (rich). A perfectly balanced (stoichiometric) fuel mixture of 14.7:1, gives a reading of around 0.5 volts.

Some O2 sensors have three wires and an internal heating element to help the sensor reach operating temperature more quickly. The heater also keeps the sensor from cooling off when the engine is idling.

An O2 sensor’s normal life span is about 30,000 to 50,000 miles. Sensors can fail prematurely if they become clogged with carbon, or are contaminated by lead from leaded gasoline or solvents from the wrong type of RTV silicone sealer.

As the sensor ages, it becomes sluggish. When the signal starts to lag behind changes in the exhaust, or becomes static, the engine experiences driveability problems (loss of power, rough idle, poor fuel mileage, or excessive emissions).

Sensor accuracy can also be affected by air leaks in the intake or exhaust manifold, or even a fouled spark plug. A misfiring plug allows unburned oxygen to pass through into the exhaust, causing the O2 sensor to give a false lean indication.

Sensor accuracy can also be affected by air leaks in the intake or exhaust manifold, or even a fouled spark plug. A misfiring plug allows unburned oxygen to pass through into the exhaust, causing the O2 sensor to give a false lean indication.

Most aftermarket replacement oxygen sensors are of a universal design which means some wire splicing may be necessary during installation. Graphite anti-seize compound should be used on sensor threads unless they are precoated. The rubber boot that fits over the sensor should not be pushed down further than half an inch from the sensor’s base.

Some vehicles are equipped with a different type of O2 sensor that has a titania rather than zirconia element. Instead of generating its own voltage signal, a titania O2 sensor changes resistance as the air/fuel ratio goes from rich to lean. Instead of a gradual change, it switches from low resistance (less than 1,000 ohms) when the mixture is rich, to high resistance (over 20,000 ohms) when the mixture is lean.

The engine computer supplies a base reference voltage of approximately one volt to the titania O2 sensor, and then reads the voltage flowing through the sensor to monitor the air/fuel ratio.

When the fuel mixture is rich, resistance in a titania sensor will be low so the voltage signal will be high (close to 1.0 volt). When the fuel mixture is lean, resistance increases and the voltage signal drops down to about 0.1 volt.

Compared to the more common zirconia O2 sensors, titania sensors have three advantages: (1) they don’t need an air reference (there is no internal venting to the outside atmosphere to plug up); (2) they have a fast warm-up time (about 15 seconds); and (3) they work at lower exhaust temperatures (they won’t cool off at idle and they can be located further downstream from the engine or used with turbochargers).

You’ll find titania O2 sensors in ’86 and later Nissan 300ZX and Stanza 4WD wagons, ’87 and up Nissan Maxima and Sentra models, and 1986-1/2 and up Nissan D21 trucks. Chrysler also uses them on the Jeep Cherokee and Wrangler (because of the sensor’s ability to handle off-road driving through water), and the Eagle Summit. .