Brake Rotor Brake Drum

How thin can rotor drums be safely turned

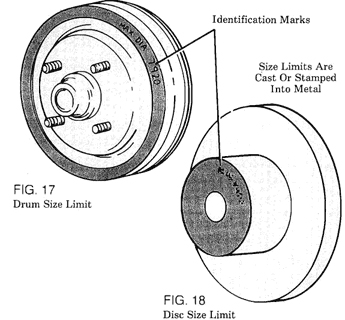

If a customer wants drums turned to a size outside the limits cast into the drum, you must refuse. They cannot be turned thinner than the minimum thickness specifications stamped or cast on the rotor or drum itself. A drum or rotor worn or turned too thin may not be able to absorb and dissipate heat quickly.

This can make the brakes run hot, accelerate lining wear, and reduce braking effectiveness. It can also lead to rotor or drum warpage and a pulsating brake pedal.

Most drums are cast with enough thickness to allow 0.090″ of wear. In other words, the difference between a drum’s diameter when new and its discard diameter is 0.090,” but that doesn’t mean you can machine a drum right up to the 0.090″ limit. You should never turn a drum that’s worn more than 0.060″ beyond its original diameter.

The 0.060″ limit leaves a 0.030″ margin for additional wear. If you turn a drum that’s worn more than 0.060,” or if the drum ends up being more than 0.060″ larger after turning, there may not be enough metal left to handle normal wear until the next brake job.

The 0.090″ discard limit is the maximum acceptable wear the drum can safely handle before the metal is too thin. Any drum worn beyond 0.060″, or that would be over 0.060″ larger after resurfacing, should never be turned on a lathe, it should be replaced.

Wear is checked by measuring diameter with a drum micrometer. If the gauge shows enough metal left to safely turn it, the drum can be resurfaced to restore and true the surface.

Like drums, the amount of wear a rotor has experienced will determine whether or not it can be resurfaced. The two-key rotor dimensions to take into account are minimum refinish thickness and discard thickness.

Discard thickness is usually cast in the rotor itself, but minimum refinish thickness must often be looked up in a reference manual or brake specification chart.

Minimum refinish thickness is the limit for resurfacing the rotor. If the rotor has worn to the point where its thickness will be less than the specified dimension after resurfacing, the rotor should be replaced.

Discard thickness is the maximum acceptable wear limit. Once the rotor is worn beyond discard thickness, it must be replaced. The difference between discard and minimum refinish thickness is the margin the vehicle manufacturer believes is necessary to allow for normal wear between brake jobs. It varies considerably from one vehicle manufacturer to the next, and according to vehicle size and type of brakes used.

The margin specified on most domestic passenger cars is around 0.015.” The range is 0.020″ to 0.030″ for most imports. A few, such as Jaguar, have as much as a 0.050″ difference between minimum refinish thickness and discard thickness.

Thickness should be measured with a micrometer at six evenly spaced points around the rotor. The smallest measurement should be used since this is how far the rotor will have to be machined to restore the surface.

Measuring at various points around the rotor will reveal any variations in rotor thickness or parallelism. Both surfaces of the rotor must be within the manufacturer’s specified tolerances for parallelism, otherwise the rotor can cause excessive pedal travel (by kicking the pads too far out as it turns), front end vibration, pedal pulsation, and chatter.

Parallelism specs recommended by various vehicle manufacturers range from as low as 0.0001″ to as high as 0.0008.” Refer to reference charts to determine how much correction, if any, is needed.

Another critical rotor dimension is runout. Lateral runout is the movement of the rotor from side to side as it turns. Excessive runout will kick the pads out as the rotor turns, creating excessive clearance requiring increased pedal travel when brakes are applied.

Runout specifications vary from as low as 0.002″ to as high as 0.006.” You should always refer to the particular specs listed by the vehicle manufacturer when checking runout.

Runout is checked with a dial indicator while the rotor is still on the car. If run-out exceeds the recommended limit, the rotor must be resurfaced or replaced.

Drums and rotors should always be inspected for heat cracks, distortion, damage, and hard spots prior to resurfacing. Cracks, damage and hard spots call for replacement. If distortion can’t be eliminated within the limits of resurfacing, replacement will also be necessary.