Brake Job

What is included in a complete brake job

A complete brake job should restore the vehicle's brake

system and braking performance to good-as-new condition.

Anything less would be an incomplete brake job.

Brake components that should be replaced will obviously

depend upon the age, mileage and wear. There is no pat

answer as to which items need replacing and which ones

don't. It's a judgement call.

A complete brake job should begin with a thorough inspection

of the entire brake system; lining condition, rotors and

drums, calipers and wheel cylinders, brake hardware, hoses,

lines, and master cylinder.

Any hoses that are found to be age cracked, chaffed,

swollen, or leaking must be replaced. Make sure the

replacement hose has the same type of end fittings

(double-flared or ISO) as the original. Don't intermix

fitting types.

Steel lines that are leaking, kinked, badly corroded, or

damaged must also be replaced. For steel brake lines, use

only approved steel tubing with double-flared or ISO flare

ends.

A leaking caliper or wheel cylinder needs to be rebuilt or

replaced. The same applies to a caliper that is frozen (look

for uneven pad wear), damaged or badly corroded.

Leaks at the master cylinder or a brake pedal that gradually

sinks to the floor tells you that the master cylinder needs

replacing.

The rotors and drums need to be inspected for wear, heat

cracks, warpage, or other damage. Unless they are in perfect

condition, they should always be resurfaced before new

linings are installed. If worn too thin, replace them.

Rust, heat, and age have a detrimental effect on many

hardware components. It's a good idea to replace some of

these parts when the brakes are relined. On disc brakes, new

mounting pins and bushings are recommended for

floating-style calipers. High temperature synthetic or

silicone brake grease (never ordinary chassis grease) should

be used to lubricate caliper pins and caliper contact

points.

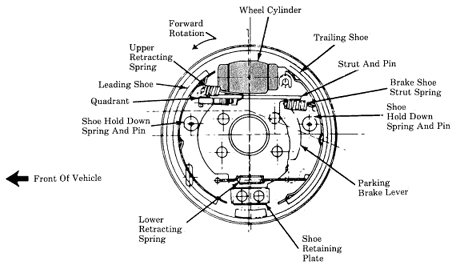

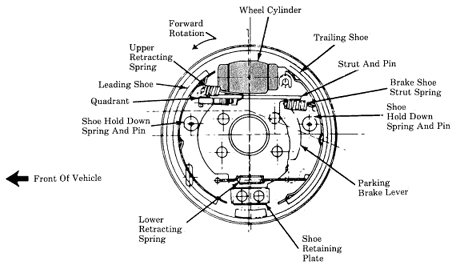

On drum brakes. shoe retaining clips and return springs

should be replaced. Self-adjusters should be replaced if

they are corroded or frozen. Use brake grease to lubricate

self-adjusters and raised points on brake backing plates

where shoes make contact.

Wheel bearings should be part of a complete brake job on

most rear-wheel drive vehicles and some front-wheel drive

cars. Unless bearings are sealed, they need to be cleaned,

inspected, repacked with wheel bearing grease (new grease

seals are a must), and properly adjusted.

As a rule, tapered roller bearings are not preloaded. Finger

tight is usually recommended. Ball wheel bearings usually

require preloading.

As a final step, old brake fluid should always be replaced

with fresh fluid.

OneStop Auto Shop

Call Today for

all of your Auto Repairs

and Maintenance

in Hollywood, Ca.!

(323) 227-9999

|