Alignment

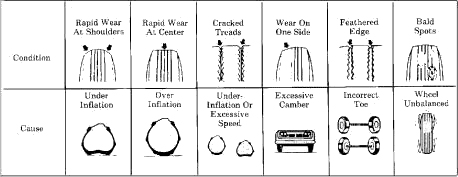

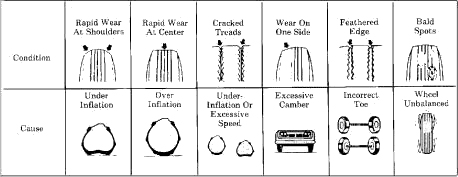

What are the significant causes of excessive tire wear

Uneven or accelerated tire wear can be caused by wheel

misalignment, worn suspension and steering components,

and/or improper tire inflation.

The most critical alignment angle with respect to tire wear

is toe. Camber is also important and can be affected by

caster. Misalignment is usually caused by worn, loose or

bent suspension and steering parts (bad tie rod ends, idler

arms, control arm bushings, ball joints, struts, etc.), but

can also be due to spring sag or improper ride height.

With tire inflation, underinflation is just as bad as

overinflation. Both can cause uneven tire wear.

Underinflation can also make a tire run dangerously hot.

For a tire to roll down the road with the least amount of

resistance and maximum directional stability, it must be

aligned with the road, parallel to the other three wheels on

the vehicle, square with the chassis, and properly inflated.

Rolling resistance is affected by a number of things, one of

which is the straightness of the tire with respect to the

direction of travel. If the tire is skewed slightly to one

side or the other (toed in or out), it will scrub as it

rolls. Scrub increases rolling resistance and also wears

away the tread, leaving a feathered wear pattern.

Toe refers to the parallelism of a front or rear wheel to

its companion on the opposite side. From a bird's-eye view,

all four wheels should be parallel to one another and

pointing straight ahead.

Toe is measured by comparing the distance between the front

edges of both tires on an axle to the distance between the

trailing edges. If the distance between the front edge is

further apart than that at the rear, wheels have toe-out.

If front is closer together than rear, wheels have toe-in.

Toe settings may be specified in inches, millimeters or

degrees. Toe is most affected by worn tie rod ends, a worn

or loose idle arm or center link, or a bent steering arm.

To minimize tire wear, rolling toe should be kept as near

zero as possible. To achieve this, the compliance or amount

of give in the vehicle's steering linkage and suspension

must be taken into consideration.

As a vehicle starts to move, rolling resistance pushes the

tires back. This compresses the couplings and rubber

fittings in the steering linkage and causes the wheels to

toe-out slightly. It isn't much of a change, but most

rearwheel drive vehicles call for static toe-in settings of

around 1/16" to 1/8" to compensate.

With front-wheel drive, the situation is different because

the front wheels pull the vehicle down the road. Engine

torque causes the wheels to toe-in under load. Most FWD

suspensions have a negative scrub radius built into the

steering geometry.

The tire pivots slightly to the outside of its centerline.

This helps to offset the tendency to toe-in. Even so, most

front-wheel drive vehicles still require toe settings of

zero to 1/8" toe out.

Toe also changes as the front wheels turn. Because the inner

and outer wheels don't follow the same path (the inner one

follows a smaller circle than the outer one), the inner

wheel must toe-out to compensate. This is called the

"Ackerman Principle of Steering" after the engineer who

invented the idea.

Toe-out depends on the angle of the steering arms with

respect to the steering knuckles and chassis. The amount by

which toe changes is called "toe-out on turns." This angle

is also listed in alignment specs and is checked by turning

the wheels on the alignment rack.

If toe-out on turns is off because of a bent steering arm,

the tires will squeal and scrub whenever the wheels are

steered.

Camber also affects tire wear. For directional stability,

the tires must be perpendicular (straight up and down) with

respect to the road. Any tilt to the inside or outside will

cause a tire to turn in that direction like a bicycle

leaning into a turn. This causes steering to pull to one

side and creates uneven wear across the tread face.

Camber is the inward or outward tilt of the wheels as viewed

from either front or rear of the car. If wheels lean in,

they have negative camber. If they lean out, they have

positive camber.

The amount of camber is always expressed in degrees and is

found by measuring the tilt of the wheels on an alignment

rack or by using a level that attaches to the wheel.

Because camber affects tire wear, the ideal situation is to

have zero running camber on all four wheels to maintain full

tread contact with the road. Like toe, camber changes as the

suspension moves up and down. To keep the wheels vertical

once the vehicle is loaded, a small amount of static

positive camber may be required.

Camber should generally be within 1/2 degree side-to-side.

Otherwise, the vehicle will lean toward the side with the

most positive camber.

Camber misalignment can be caused by a sagging spring, a

bent strut, bent spindle, worn control arm bushing, worn

ball joint, or mislocated strut tower (too far in or out).

Camber corrections are made by replacing worn parts and/or

by realigning the suspension using either the factory

adjustments (cams, shims or elongated holes) or aftermarket

aids.

OneStop Auto Shop

Call Today for

all of your Auto Repairs

and Maintenance

in Hollywood, Ca.!

(323) 227-9999

|